Categories List

SCAFFOLDING

- Tower (Customized)

- H Frame

- Cuplock Ledger/Horizontal

- Cuplock Vertical

- Coupler / Pipe Clamp

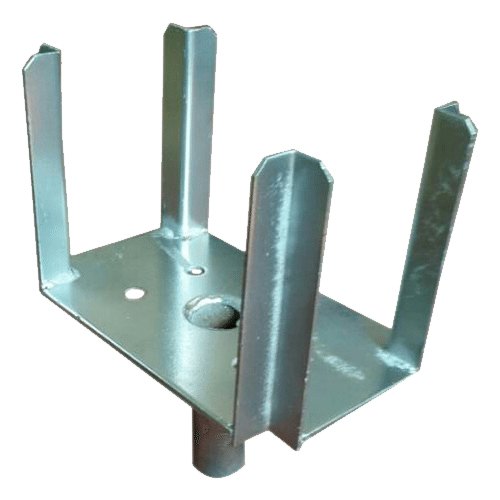

- Base Plate

- Base Jack.

- U Jack.

- Sleeve Coupler

- Forged Coupler / Forged Pipe Clamp

- Walkway Plank

- Bracing Pipe

- Joint Pin

- Spigot Pin.

- Toe Board

- Ladder Clamp

- Board Clamp

- Ladder

- MS Challi

- Beam Clamp

- Ringlock & accessories

Doka Formwork Materials

By consistently finance in new producing technologies and in increasing our production capability,operating strategically with audited suppliers and regularly upskilling our wood- and metal formation production workers GRS have extremely economical in-house production operations on a awfully solid footing. We are top manufacturer and supplier of Doka formwork materials including H20 Beam, H20 Beam Clamp, H20 Timber Beam Clamp, Peri Clamp, Prop Fork Head, Push Pull Prop and many more.

We have Doka formwork solutions for a wide range of building projects, from housing developments to transportation infrastructure and power plants, as well as the tallest towers. For any construction project or requirement, you can choose from a wide range of formwork systems and components available here.

What is Doka Formwork?

Doka Formwork is a temporary support that acts as a mould for new concrete, allowing it to be poured and cast in the correct shape, gain initial strength, then harden and mature which provides construction support.

Doka formwork is a framed structure that is frequently utilized to produce an enclosed structure in building constructions. Supporting construction frames, on the other hand, are one-sided frames that are required when concrete is poured onto a surface, such as an underground train station, tunnel, or mine.

To form unique shapes, large area formwork is made to project-specific designs. Finally, column formwork enables columns to be cast and placed on site, as well as to precise dimensions. Doka formwork includes variety of products in each of these categories, assuring that you can get precisely what you need.

Advantage of Doka Formwork

- Formwork must be capable of shaping and supporting the fluid concrete until it hardens in order to keep it contained.

- Strength: The formwork must be able to safely handle the dead weight of the fluid concrete, labour weight, equipment weight, and any environmental loadings without deformation or danger

- To keep the grout from leaking out, all seams in form work must be either tightly fitting or sealed with form tape. If the grout leaks, the concrete will begin to leak at that point. Surface honeycombing is caused by leaks.

- Accuracy: Formwork must be precisely laid out so that the finished concrete product is in the correct location and has the proper shape and proportions.

- Form panels and units should be constructed so that their maximum size does not exceed what can be handled readily by human or mechanical methods. In addition, all formwork must be planned and built to allow for modifications, levelling, easing, and striking without causing harm to the formwork or the concrete.

- Finish and reusability: the form face material must be capable of reliably delivering the necessary concrete finish (smooth, textured, featured or exposed aggregate etc.) It should also achieve the required number of reuses at the same time.

- Concrete placement access: any formwork system must allow for concrete placement. The scope of this service will be determined by the ease with which the concrete activities may be carried out.

- All of the formwork is really pricey. On average, formwork accounts for around 35% of the overall cost of every finished concrete unit or element; of this, little over 40% can be attributedto material for formwork and 60% to labour. As a result, the formwork designer must not only consider the maximum number of times a form may be reused, but also create a design that reduces the amount of time required for erection and striking.

Product List

H20 BEAM CLAMP

GRS Scaffolding is a trusted supplier of H20 Beam Clamps. Our high-quality clamps provide secure and efficient connections for H20 beams. With our expertise and commitment to excellence, we deliver reliable and durable solutions. Trust GRS Scaffolding for all your H20 beam clamp requirements and experience superior construction support.

View Details Enquiry

H20 BEAM

GRS Scaffolding offers top-quality H20 Beams for construction projects. Our sturdy and reliable beams provide excellent load-bearing capabilities and structural support. With our commitment to safety and durability, we deliver H20 Beams that meet industry standards. Trust GRS Scaffolding for all your H20 Beam requirements and ensure efficient and robust construction.

View Details Enquiry

H20 TIMBER BEAM CLAMP

GRS Scaffolding provides reliable H20 Timber Beam Clamps for construction needs. Our high-quality clamps ensure secure and efficient connections with H20 timber beams. With our expertise and commitment to safety, we deliver durable and compliant solutions. Trust GRS Scaffolding for all your H20 timber beam clamp requirements and experience superior construction support.

View Details Enquiry

PERI CLAMP

GRS Scaffolding offers dependable PERI Clamps for various construction applications. Our high-quality clamps ensure strong and secure connections, enhancing safety and efficiency on the job site. With our commitment to quality and customer satisfaction, trust GRS Scaffolding for all your PERI Clamp requirements and experience reliable construction support.

View Details Enquiry

PROP FORK HEAD

GRS Scaffolding provides reliable Prop Fork Head solutions for construction projects. Our high-quality fork heads offer sturdy support and precise adjustment capabilities. With our commitment to excellence and safety, we deliver durable and efficient products that meet industry standards. Trust GRS Scaffolding for all your Prop Fork Head requirements and ensure reliable construction support.

View Details Enquiry

PUSH PULL PROP 1

GRS Scaffolding offers reliable Push Pull Props for construction applications. Our high-quality props provide robust support and easy adjustment capabilities. With our commitment to safety and durability, we deliver efficient and compliant solutions. Trust GRS Scaffolding for all your Push Pull Prop needs and experience superior construction support.

View Details Enquiry

PUSH PULL PROP

GRS Scaffolding offers reliable Push Pull Props for construction applications. Our high-quality props provide robust support and easy adjustment capabilities. With our commitment to safety and durability, we deliver efficient and compliant solutions. Trust GRS Scaffolding for all your Push Pull Prop needs and experience superior construction support.

View Details Enquiry

STEEL WALLER BEAM

GRS Scaffolding provides sturdy Steel Waller Beams for construction projects. Our high-quality beams offer excellent structural support and stability. With our commitment to safety and reliability, we deliver durable and efficient solutions. Trust GRS Scaffolding for all your Steel Waller Beam requirements and ensure a robust construction framework.

View Details Enquiry